Batch Coding Machine

Batch Coding Machine

Brand:

Others

Price ₹

21,000.00

| General Detail: | |

| Model | Batch Coding Machine |

| Material | Mild Steel |

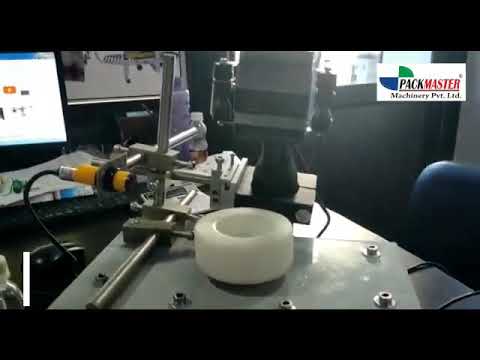

PET Bottle Batch Coding Machine Indian

Brand:

Others

Price ₹

22,000.00

| General Detail: | |

| Model | Batch Coding Machine |

| Voltage | 230v AC |

| Automation Grade | Automatic |

| Material | all |

| Others: | |

| Print Speed | 2000/per/H |

| Model Name/Number | PM 18PBC |

| Ink Color | Black |

| Capacity | 2000/per/H |

| Brand | PACKMASTER |

Batch coding machines

Brand:

Others

Price ₹

34,000.00

| General Detail: | |

| Model | Batch coding machines |

| Model | PM-074 |

| Voltage | 230v AC |

| Usage/Application | industrial,pharma,food,etc. |

| Automation Grade | Automatic |

| Material | S.S. Body |

| Others: | |

| Ink Colour | s.s. |

| Coding Speed | 3600-5000 per hours |

| Model Name/Number | 380 |

| Brand | Packmaster |

Solid Hot inK Coding Machine

Brand:

Others

Price ₹

32,000.00

| General Detail: | |

| Model | PM-64BC |

| Material | S.S. Body |

| Voltage | 230v AC |

| Automation Grade | Automatic |

| Usage/Application | industrial,pharma,food,etc. |

| Others: | |

| Brand | Packmaster |

| Coding Speed | 3600-5000 per hours |

| Ink Colour | s.s. |

| Item Code | 380 |

| Recommended Order Quantity | 1 |

| Model Name/Number | 380 |

| Weight | 24 aprox |

if you are interested, please fill the below details: